Summary:If you are thinking of getting an Agricultural spray pump, then you are in the right place. You can read more about thes...

If you are thinking of getting an Agricultural spray pump, then you are in the right place. You can read more about these pumps by reading this article. In this article, you will learn about the types, maintenance, and cost of this equipment. It also includes helpful tips on purchasing the right pump for your needs. We have provided you with a list of the features to look for in the best pump. After reading this article, you will have a clear picture of what an agricultural spray pump is.

Agricultural spray pumps

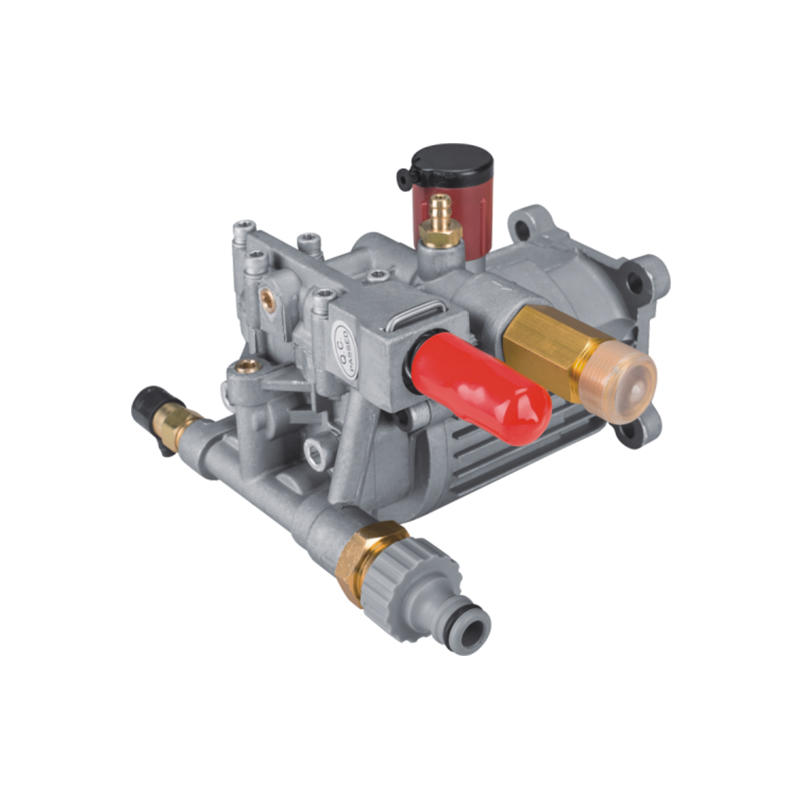

Agricultural spray pumps are an important part of agricultural machinery. Farmers rely on them to apply liquid fertilizers, pesticides, and herbicides to crops. They help farmers spray their crops efficiently, and are reliable suppliers. Several manufacturers offer agricultural spray pumps, but you must consider the specific needs of your farm before selecting a model. Consider the following factors when shopping for an agricultural spray pump. Agricultural sprayers come in different boom sizes. The boom size may need to be adjusted to accommodate different crop varieties.

Different crops require different types of

agricultural spray pumps. For example, soybeans require high volume pumps, while sunflowers require low volume ones. Agricultural spray pumps come in six general types: piston, diaphragm, irrigation-injection, and centrifugal. You need to choose the GPM and pressure according to your requirements. Some pumps come with extra features, like adjustable flow and auto-resistance. The GPM and pressure should be suitable for the type of crop you are growing.

Agricultural spray pumps are used in paddy, wheat, sorghum, cotton, and mustard cultivation. The demand for these pumps comes from various states in India, but the highest volume is in Punjab, Uttar Pradesh, Rajasthan, Andhra Pradesh, and Maharashtra. Some of the leading manufacturers of agricultural spray pumps are in China. While Chinese manufacturers can produce agricultural spray pumps at lower costs, Indian manufacturers cannot match their quality or price.

Various types of rollers are available. Some types have higher resistance to agricultural chemicals than others, such as Teflon. However, they tend to wear out more easily when spraying wettable powders. Other types feature polypropylene or nylon rollers, which are better suited to weak or lubricated solutions. A good lubricant and proper maintenance will extend the pump's lifespan. You may want to consider adding a few adjuvants to your spray solution.

Diaphragm pumps are also available. Diaphragm pumps can deliver high volumes of water at low pressures. Diaphragm pumps have a smooth action. They are a popular choice for agriculture and other low-pressure applications. They feature a self-priming mechanism and are available with a variety of options. A good abrasive material such as grass seeds and weed killers will rapidly wear the gears and housing of gear pumps.

Types of pumps

There are several types of agricultural spray pumps available, ranging from piston and diaphragm pumps to rotary air compressors and in-line fuel cells. Each type has its own specific requirements for flow rate and pressure, but they are all generally suitable for spraying a wide range of substances. Pumps used in sprayers are also crucial for the application of a variety of chemical products. To ensure the safe and efficient application of chemical products, the pump must be capable of providing a constant flow rate. In addition, it must be able to operate a hydraulic agitation system and deliver the required volume to the nozzles. Generally, pumps in this class are self-priming and are capable of producing a range of pressures up to 725 PSI.

Piston pumps feature piston mechanisms that compress system fluid for uniform nozzle output. These pumps are best suited for high-pressure applications, including spraying livestock and crops with insecticides and fungicides. Piston pumps also have long service lives and are self-priming. Piston pumps are also available in different flow rates and pressure ranges, which makes them a flexible choice for farmers and growers alike. There are three basic types of agricultural spray pumps, including rotary air compressors, piston pumps, and piston-driven pumps.

Piston pumps are typically found beneath a supply tank, with the pump located below it. As with any pump, the discharge line must be properly connected to prevent plugging. A strainer in the discharge line prevents the nozzles from clogging while preventing a blockage in the pump's input. The pumps typically have two control valves on their discharge lines - one for the agitation line, and one for the spray boom.

A modern agricultural sprayer pump has multiple power sources, including air, gasoline, hydraulic, and diaphragm. Regardless of which power source is used, modern sprayer pumps are designed to be compatible with compatible work equipment. Choose a sprayer pump based on your desired GPM flow rate, operational pressure capabilities, speed ranges, and power drive options. Ideally, you will choose a pump rated at 20% higher than the flow rate you require.

Maintenance of pumps

Agricultural spray pumps need regular maintenance to remain reliable and in top shape. Proper agitation is essential in granular products, since they can starve and clog the pumps. Hence, the tank should be rinsed out at least three times. Besides, it is necessary to clean the accessories and the pump itself. Performing a triple rinse will ensure that all dirt and debris are removed from the pump and prevents the chemical from mixing. Before starting work, make sure to empty the tank, drain it and clean the sprayer thoroughly. If not, the sprayer should be switched off and the nozzle cleaned thoroughly.

Agricultural spray pumps require routine maintenance, especially the suction hose. Suction filters are placed on the top of the tank and in the suction line going to the pump. Partially clogged filters can cause erratic flow, reduced pressure, and even pump cavitation. To check if the filter is clogged, pressurize the tank and pull the intake hose against the tank. Ensure that the suction line is free of debris and rust to avoid clogging the pump.

Cost of pumps

The cost of agricultural spray pumps can vary widely, depending on the type of pump used and the quantity of chemicals to be sprayed. Different situations require different pressure and flow rates. Pumps need to be durable, because they often come in contact with harsh chemicals, such as fertilizers. Some pumps have chemical corrosion protection built into their design, which can make them more expensive. You may also want to consider adding adjuvants to your spray solution to reduce the risk of premature wear.

The flow rate and pressure of the spray liquid need to be pumped to the desired level for the best results. For this, a pump must have a reserve capacity of 10 to 20 percent. Pumps lose their efficiency over time due to wear and drive friction, as well as leakage. A good rule of thumb is that one horsepower equals 50 gpm x 40 psi. However, the lower HP does not necessarily mean better performance.

Agricultural spray pumps are used for a variety of purposes, ranging from livestock to crops. Depending on the application, a piston pump may require a surge tank at the pump outlet to reduce the characteristic line pulsation. This type of pump may also be difficult to use in a tight, steep landscape. A high-quality pump can save you both time and money. So, if you're looking for a reliable pump for your farming needs, consider a piston pump.

When it comes to power, consider the Neptune HTP Gold Plus. It is a popular choice among farmers due to its low cost and sturdy construction. It is easy to operate, has a large tank, and is 3-5 hp. It can spray up to 25 kg/cm2 and can run with 20 to 45 kg pressure. The Neptune HTP Gold Plus is available for Rs 5999. A similar model is also available in smaller sizes, such as a two-liter capacity.

Agricultural spray pump costs can vary depending on the type of sprayer you choose. Centrifugal pumps are common, but more expensive, and use a belt and sheave assembly to increase impeller speed. Other pump types include piston and diaphragm pumps. The pump you choose should match the type of fluid you're using, and how much volume you'll be pumping. And a good pump should last you for several years.

0086-576-88133277

0086-576-88133277

0086-576-88129859

0086-576-88129859