Manual airless electric spray gun

Handheld Airless Electric Spray Guns Reviews

No compressors, no turbines, no hoses-no problem! Airless sprayers provide new options for rapid and efficient spraying.

The compact airless electric spray gun is a novice in the field of spray guns. This stand-alone hand tool can quickly spray paints, stains, varnishes or varnishes without dilution with solvents. Since they are relatively new, we think we should look at some of them and see if they should be introduced into our stores and houses.

How does it work?

Most of the spray guns I have used are connected to the air source: the compressor of a standard spray gun or conversion gun; the turbine for the HVLP spray gun. By injecting a flow of oil into the rapidly moving air, the oil is atomized into droplets in the air.

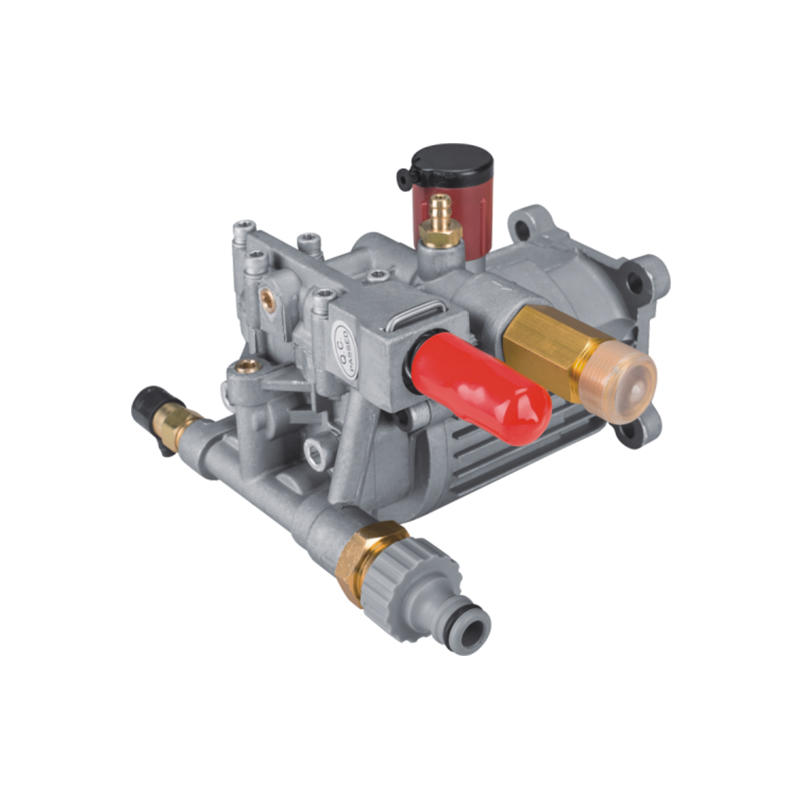

As the name suggests, no air means no air at all. It does not mix the liquid with the air, but forces the very high-pressure paint flow through a finely shaped hole, causing it to spread and atomize, so that the liquid breaks into droplets when it comes out of the spray gun.

You can think of it as a high-pressure version of a spray head, or a nozzle on a garden hose. Both are examples of airless spraying. In this case, the liquid pump will generate a higher pressure, allowing the spray gun to atomize materials thicker than water.

You may have seen house painters use a large airless system, which consists of a pump, usually on a shelf, the hose of the pump goes from a bucket of paint to the pump to the gun. The gun here is a smaller version of the same technology

Stand-alone handheld device that can be plugged into a standard power outlet. One of the guns we tested was battery-powered, so there were n’t even wires to handle.

The first is versatility. Airless spray guns will spray almost any topcoat at full viscosity, usually without thinners at all. The same gun can usually handle house paint, deck paint, thin paint, oil-based polyurethane or your favorite furniture stains that are almost impossible to restore.

There is no need to reduce the surface finish, which not only saves the cost of buying expensive solvents (except for solvents that need to be cleaned), but also means that each layer of surface finish contains more solids, so it generates faster. When you reduce the paint by 50% for spraying, all the solvent must evaporate, leaving at most 50% of the wet thickness you use.

Transfer efficiency is a measure of the paint actually sprayed from the spray gun falling on the wood. Although other spray methods are different, laboratory tests have repeatedly shown that airlessness is by far the most effective method. If no air is blown on and after, a high percentage of paint will eventually adhere to the wood.

Speed is another advantage. In terms of volume, the airless spray gun moves much faster than any other type of spray gun. Even the smallest of our test samples can be sprayed with a gallon of paint in about 10 minutes.

Disadvantages?

On the other hand, speed can also be disadvantageous. Anything that can move so much finish quickly is difficult to control, especially if you only want to apply a thin coating. However, this generation of handheld airless guns can control both volume and power, allowing you to dial back the flow rate to obtain thinner materials that may require sparse spraying. Nevertheless, I hope to set aside some time to practice spraying cardboard and wood chips.

Perhaps the biggest disadvantage is weight. Because you carry a small pump in addition to cups or paint, these guns weigh quickly. One privilege: they all have available or included accessories that allow you to remove the cup part and connect the hose directly to the paint or surface treatment tank. At least that's it, you don't need to carry a quart of paint besides the gun.

As a professional China electric high pressure power washer manufacturers and commercial high pressure washers factory, We sincerely invite the global prospective customers to pay a visit and have a good cooperation for a splendid future together.

Wholesale High Quality Knapsack Sprayer Exporter Agriculture has come a long way from the traditional methods of farming, with technological advanceme...

ALL>>

Sale OEM Electric Agriculture Battery Sprayer Maker Agriculture has come a long way over the years, and farmers are always looking for ways to improve...

ALL>>

No.1008 Qihang Road, Binhai Industry Zone, Jiaojiang, Taizhou, Zhejiang, China.

0086-576-88133277

0086-576-88133277

0086-576-88129859

0086-576-88129859

Copyright © Taizhou City Hangyu Plastic Co., Ltd. All Rights Reserved.

Olinda

![HY-18L [NO 1605-D] HY-18L [NO 1605-D]](/tzhangyusj/2020/10/19/024.jpg?imageView2/2/format/jp2)